The Process

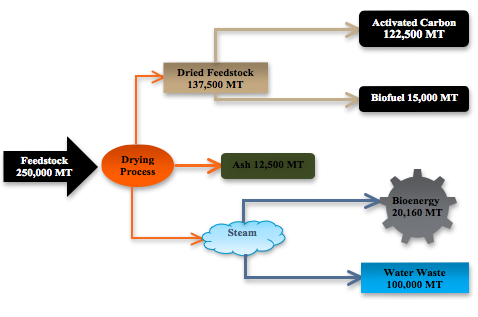

Canadian Nutraceutical Distillators has acquired proprietary Intellectual Property that enables the continuous pyrolysis process that can produce bioenergy components from feedstock. The underlying technology that provides the company with the highest production output is a patented pyrolysis technology which safely and continuously processes organic material into activated carbon, biofuel and bioenergy. The proprietary technology enables Canadian Nutraceutical Distillators to use a much smaller processing footprint while creating much higher conversion rates of feedstock to generate the final products. Some of the advantages of this unique technology include:

Canadian Nutraceutical Distillators’s technology is scalable, allowing maximum capital equipment return on investment. Each site location can be optimally designed to match feedstock agreements. As feedstock opportunities grow in an existing location, additional units can be installed in parallel while sharing steam generation, activator and input/output handling. Current feedstock includes:

- Low consumption of energy in the plant

- Long term and low cost of supply of feedstock

- Environmentally Green - this project would turn biowaste into bioenergy

- The company’s system and business model is not dependent on the price of fossil fuels for production purposes.

- Every unit promises significant opportunities for the regional labour market.

Canadian Nutraceutical Distillators’s technology is scalable, allowing maximum capital equipment return on investment. Each site location can be optimally designed to match feedstock agreements. As feedstock opportunities grow in an existing location, additional units can be installed in parallel while sharing steam generation, activator and input/output handling. Current feedstock includes:

- Logging and mill residues;

- Wood from fire and insect-killed forest stands;

- Wood from thinnings, and non-merchantable timber (chipped, spruce, pine and fir).